SMEMACH:Austempered Ductile Iron

In the field of advanced materials, austempered ductile iron (ADI) is a star material. Its exceptional mechanical properties and wear resistance have earned it widespread application in industries such as automotive manufacturing, construction machinery, and rail transit. The revision of China's national standard GB/T 24733-2023, "Austempered Ductile Iron Castings," marks a significant milestone in the development of my country's ADI industry technology system, propelling the sector into a new era.

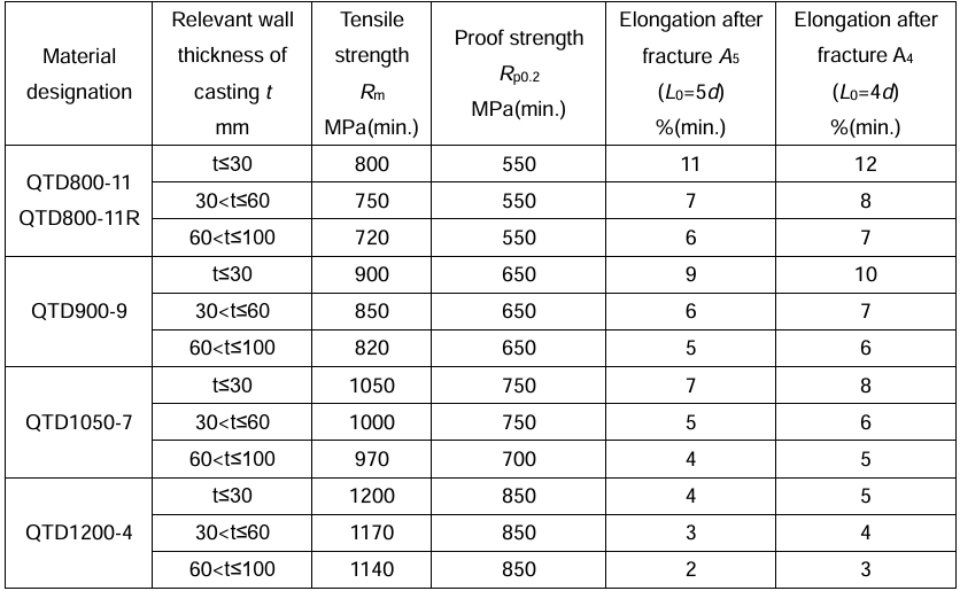

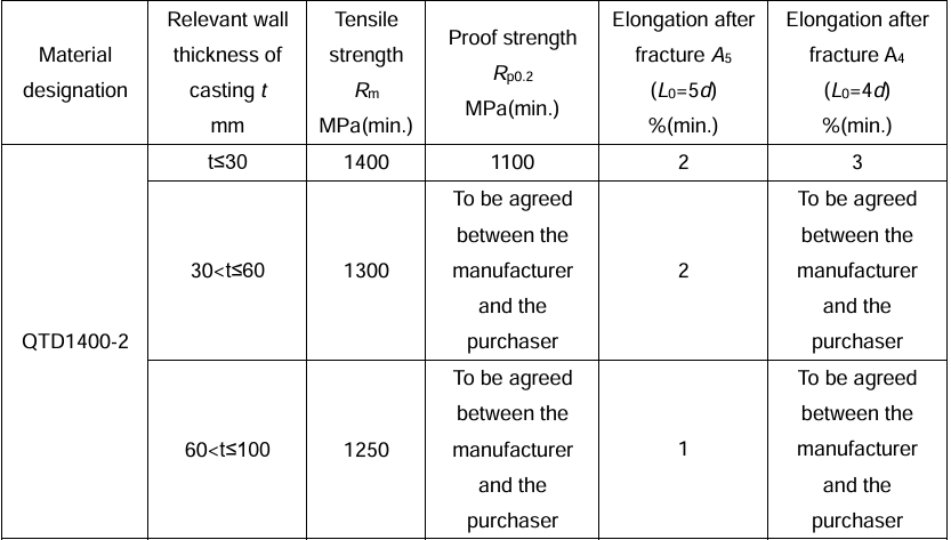

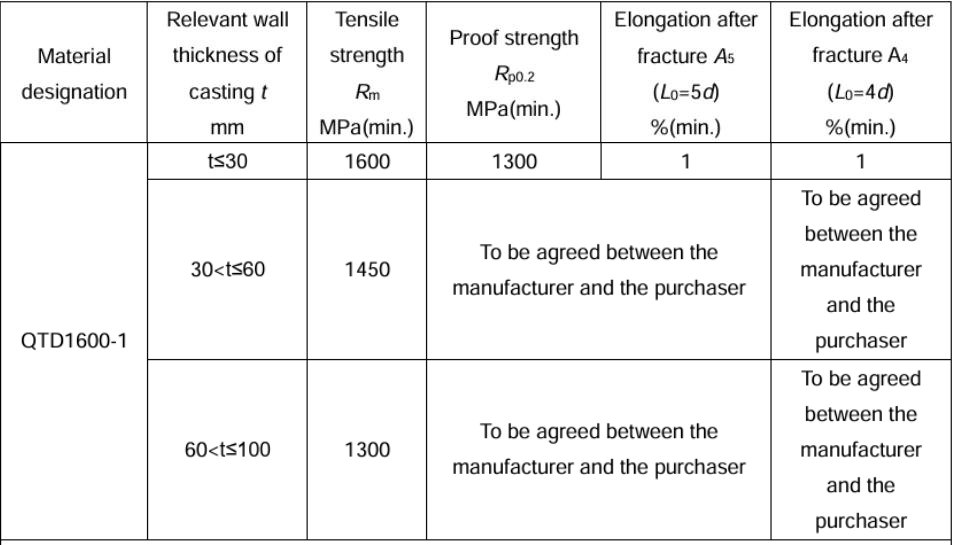

GB/T 24733-2023 officially came into effect on September 7, 2023, replacing the 2009 version. This revision was led by the Zhengzhou Machinery Research Institute in collaboration with 25 industry-leading organizations, including FAW Foundry and Dongfeng Motor. The revision adds high-performance grades such as QTD1600-1 and scientifically adjusts core specifications such as yield strength and elongation. This standard, which non-equivalently adopts the international standard ISO 17804:2020, establishes an ADI quality control system covering various processes, including sand casting, metal mold sand coating, and investment casting, laying a solid foundation for standardized and high-quality development of the industry.

The new standard divides ADI materials into six grades, forming a comprehensive performance gradient from QTD800 to QTD1600-1. Each grade has distinct performance characteristics and application scenarios.

Yield strength ≥ 800 MPa, elongation ≥ 3%, suitable for components such as gears and brackets subject to medium loads. Its adoption in a specific automotive transmission project reduced part weight by 25% and increased fatigue life by three times, demonstrating its significant potential in automotive parts manufacturing.

Yield strength ≥ 900 MPa, elongation ≥ 2%, widely used in hydraulic cylinders for construction machinery. SMEMACH's custom-made QTD900 crankshaft for mining machinery companies maintains excellent toughness in extremely cold conditions of -40°C, breaking through the bottleneck of traditional cast iron's low-temperature brittle fracture and ensuring stable operation of construction machinery in extreme environments.

Designed specifically for high-stress environments, it offers a yield strength ≥1050 MPa and an elongation ≥1.5%. In the rail transit sector, it successfully replaces some forged steel parts, enabling lightweight manufacturing of key bogie components, improving operational efficiency and reducing energy consumption, in line with the concept of green development.

Ultra-high-strength ADI material with a yield strength ≥1200 MPa and an elongation ≥1%. SMEMACH's QTD1200 connecting rod demonstrated fatigue resistance comparable to forged steel in diesel engine testing, reducing manufacturing costs by 40%, and has broad prospects in automotive engines and other fields.

Primarily targeted at high-end applications such as aerospace, it offers a yield strength ≥1400 MPa and an elongation ≥0.8%. After adoption, a satellite component achieved dimensional stability of 0.002mm/m under vacuum, meeting the stringent aerospace requirements for high-precision and high-reliability materials.

This new standard's signature grade boasts a yield strength ≥1600MPa and an elongation ≥0.5%, setting a new ADI material strength record. Utilizing nano-austenite strengthening technology, it maintains excellent toughness while improving impact resistance by 50% compared to traditional hardened steel, providing a high-quality material choice for high-end equipment manufacturing.

Following Principles and Practical Strategies: The standard requires that grade selection adhere to the "performance matching principle," which can be considered based on load type, environmental factors, and cost optimization.

For dynamic loads requiring high toughness, high-elongation grades, such as QTD900, are preferred. For static loads, strength indicators, such as QTD1400, can be prioritized.

Low-temperature operating conditions require verification of impact toughness at -20°C or -40°C. Corrosive environments require additional coating treatment to enhance corrosion resistance. Cost Optimization:

CAE simulation analysis allows for the selection of the lowest grade while ensuring performance is met. SMEMACH's established "material-process-cost" database enables rapid generation of selection solutions. For example, in an agricultural machinery gear project, replacing QTD1200 with QTD1050 reduced unit costs by 18%, resulting in significant cost savings.

The ADI grade system established by GB/T 24733-2023 demonstrates China's innovative strength in materials science and provides critical support for the transformation and upgrading of the manufacturing industry. Companies like SMEMACH, through technological iteration and industrial application, are driving the transformation of ADI materials from an "alternative option" to a "preferred option," contributing Chinese expertise to global high-end equipment manufacturing. In the future, ADI materials are expected to flourish in even more fields and achieve remarkable results.

(The document can be searched for GB/T 24733-2023 in the China National Standards Full Text Public System https://openstd.samr.gov.cn, and can be read online and partially downloaded.)

ADI China International Standard-GB/T 24733-2023

International Standards for ADI Casting:ISO 17804:2005

ADI (Austempered Ductile Iron) : the "Wolverine" blade in the logging industry