| Description: | |

| Casting Material: | Alloy Steel |

| Design Software: | CAD,PRO/E,SolidWorks |

| Forging Process: | Closed Die Forging Process |

| Heat Treatment: | Quenching and Tempering |

| Machining: | CNC Machining |

| Surface Finishing: | Shot Blasting, Galvanized/Hot Dip Galvanized, Powder Coated, Spray Painting |

| Package: | Fumigation-free Pallet or Wooden Case |

Shackles: the unsung heroes of lifting and rigging.

Where safety and reliability are non-negotiable, our forged bow and dee shackles (209 / 210 / 2130 / 2150 and beyond) out-perform screw-pin types every time.

- Lock-tight connection, zero spin-off under vibration or side-load

- Hot-drop forged body + alloy-steel pin, grain flow uninterrupted

- Proof load 2 × WLL, 100 % mag-particle inspected

1/4" → 4" (6 mm → 100 mm) | 0.5 t → 150 t

800+ dies ready, no MOQ, 48 h dispatch for standard sizes

HDG 80-120 µm | 316L electro-polished | custom epoxy

EN 13889 / ASME B30.26 / BV-DNV third-party witness available

We forge, machine, heat-treat, test and pack in-house—year-round volume for rigging stockists, crane OEMs and offshore EPCs.

Send your WLL or drawing, we’ll open the right die today.

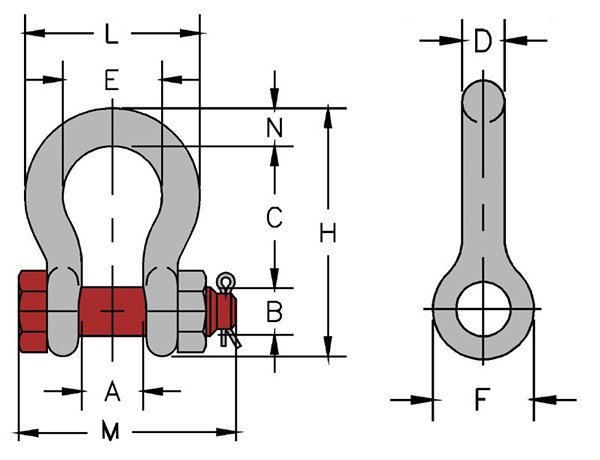

| Size | WLL | Weight | Dimensions(mm) | Tolerance | ||||||||

| (in) | (Ton) | (Kg) | A | B | C | D | E | F | H | L | M | - |

| 1/4" | 0.5 | 0.048 | 11.9 | 8 | 28.7 | 6.4 | 19.8 | 15.7 | 46.7 | 32.6 | 42 | ±5% |

| 5/16" | 0.75 | 0.1 | 13.5 | 9.5 | 31 | 7.9 | 21.3 | 19 | 53 | 37.3 | 49 | ±5% |

| 3/8" | 1 | 0.16 | 16.8 | 11.1 | 36.6 | 9.6 | 26.2 | 23.4 | 63 | 45.4 | 59.5 | ±5% |

| 7/16" | 1.5 | 0.22 | 19 | 12.7 | 43 | 11.2 | 29.5 | 27 | 73.9 | 51.9 | 65 | ±5% |

| 1/2" | 2 | 0.34 | 20.6 | 16 | 47 | 12.7 | 33 | 30 | 83.5 | 58.5 | 77.5 | ±5% |

| 5/8" | 3.25 | 0.68 | 27 | 19 | 60 | 16 | 42 | 39 | 106 | 74 | 97 | ±5% |

| 3/4" | 4.75 | 1.11 | 31.8 | 22.1 | 71 | 19 | 51 | 47 | 125 | 89 | 109 | ±5% |

| 7/8" | 6.5 | 1.66 | 36.6 | 25.1 | 84 | 22 | 58 | 54 | 147 | 102 | 123 | ±5% |

| 1" | 8.5 | 2.35 | 43 | 28.1 | 96 | 25 | 68 | 60 | 166 | 118 | 139 | ±5% |

| 1 1/8" | 9.5 | 3.22 | 46 | 31.7 | 107 | 28.5 | 74 | 68.5 | 185.5 | 130 | 149 | ±5% |

| 1 1/4" | 12 | 4.98 | 51.5 | 35.1 | 119 | 32 | 82 | 76 | 208 | 146 | 171 | ±5% |

| 1 3/8" | 13.5 | 6.36 | 57 | 38 | 131 | 35 | 89 | 84 | 228 | 159 | 186 | ±5% |

| 1 1/2" | 17 | 8.24 | 60.5 | 41.5 | 148 | 38 | 98 | 92 | 254 | 174 | 194 | ±5% |

| 1 3/4" | 25 | 14.29 | 73 | 50.8 | 177 | 45 | 127 | 109 | 303 | 217 | 328 | ±5% |

| 2" | 35 | 20.1 | 82.5 | 57.1 | 197 | 51 | 146 | 127 | 341 | 248 | 260 | ±5% |

| 2 1/4" | 42.5 | 31.4 | 95 | 63 | 221 | 57 | 160 | 143 | 283 | 274 | 302 | ±5% |

| 2 1/2" | 55 | 43.6 | 105 | 69.8 | 264 | 66.5 | 184 | 150 | 455 | 321 | 328 | ±5% |

| 3" | 85 | 67 | 127 | 85 | 328 | 76 | 200 | 165 | 546 | 371 | 378 | ±5% |

| 3 1/2" | 120 | 113 | 133 | 95 | 371 | 92 | 229 | 203 | 632 | 432 | 425 | ±5% |

| 4" | 150 | 141 | 140 | 107 | 368 | 104 | 254 | 228 | 651.5 | 457 | 452 | ±5% |

Building 1,No. 8B Hong Kong Middle Road, Qingdao, China.

© 2019 Sinostar Industrial Machinery Co., Ltd. All Rights Reserved.

Powered by HiCheng